In the intricate web of modern manufacturing operations, ensuring the seamless functioning of machinery and production lines is paramount, especially in sectors like food production where quality and safety are non-negotiable.

With the advent of technology, traditional methods of maintenance have evolved into sophisticated strategies aimed at pre-empting failures rather than merely reacting to them. Among these, vibration analysis has emerged as an effective condition monitoring tool, offering a proactive approach to maintenance that enhances efficiency, reduces downtime, and safeguards product integrity.

Nowhere is this more evident than in the UK's food factories, where the convergence of stringent regulations and consumer expectations necessitates meticulous maintenance protocols.

Understanding Vibration Analysis:

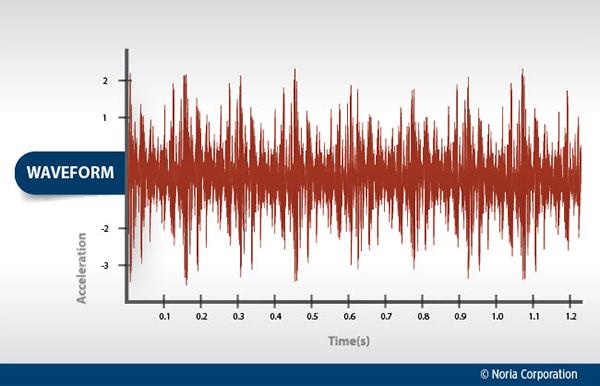

At its core, vibration analysis involves the study of machinery vibrations to assess their health and performance. Every machine, from conveyor belts to mixers, emits distinct vibrations during operation. These vibrations carry a wealth of information about the machine's condition, including factors such as alignment, balance, bearing wear, and structural integrity. By capturing and analysing these vibrations using specialised equipment and software, maintenance teams can detect anomalies indicative of potential issues before they escalate into costly breakdowns.

Unlock the full potential of your machinery with our comprehensive vibration analysis solutions tailored for UK food factories. Fill in the form at the foot of this article to request a callback ↓

Uses of Vibration Analysis in Condition Monitoring:

Early Fault Detection: Vibration analysis serves as a proactive diagnostic tool, enabling early detection of faults or abnormalities in machinery. By monitoring vibration signatures over time, technicians can identify subtle changes that may signify impending failures, allowing for timely intervention.

Predictive Maintenance: Armed with insights gleaned from vibration analysis, maintenance teams can transition from reactive to predictive maintenance strategies. By predicting when equipment is likely to fail based on vibration patterns, resources can be allocated more efficiently, minimising unplanned downtime and maximising productivity.

Optimised Performance: Fine-tuning machinery for optimal performance is essential in food production, where consistency is key. Vibration analysis aids in optimising equipment performance by identifying inefficiencies such as misalignments or unbalanced components, thereby enhancing throughput and product quality.

Safety Assurance: In the food industry, equipment malfunctions can jeopardise both product integrity and employee safety. Vibration analysis helps mitigate these risks by flagging potential hazards such as worn bearings or excessive vibration levels, prompting timely corrective action to prevent accidents.

Benefits of Vibration Analysis in UK Food Factories:

Compliance with Regulatory Standards: The UK food industry operates within a stringent regulatory framework aimed at ensuring food safety and quality. By implementing vibration analysis as part of their maintenance regimen, factories can demonstrate compliance with regulatory requirements by proactively addressing equipment integrity and performance.

Cost Savings: Downtime in food production facilities can have significant financial implications, not only in terms of lost production but also potential fines for non-compliance or product recalls. Vibration analysis helps minimise downtime by averting unexpected breakdowns, resulting in substantial cost savings over time.

Enhanced Product Quality: Consistency is paramount in food manufacturing, where even minor deviations in product quality can have far-reaching consequences. By maintaining machinery in optimal condition through vibration analysis, factories can uphold the integrity of their products, safeguarding brand reputation and consumer trust.

Sustainable Operations: Sustainable practices are increasingly prioritised in the food industry, driven by consumer demand for ethically sourced and environmentally responsible products. Vibration analysis supports sustainability initiatives by prolonging the lifespan of equipment, reducing the need for premature replacements, and minimising resource consumption.

Challenges and Future Outlook:

While the benefits of vibration analysis in UK food factories are undeniable, challenges persist in its widespread adoption. These include initial investment costs, the need for specialised training, and integrating vibration analysis into existing maintenance workflows. However, advancements in sensor technology, data analytics, and predictive maintenance algorithms hold promise for overcoming these hurdles, paving the way for more comprehensive condition monitoring strategies.

In conclusion, vibration analysis stands as a linchpin in the arsenal of tools available to UK food factories for ensuring the reliability, efficiency, and safety of their operations. By harnessing the power of vibration analysis as part of their condition monitoring initiatives, these factories can navigate the complex landscape of modern manufacturing with confidence, meeting regulatory requirements, optimising resources, and delivering products of the highest quality to consumers.

Unlock the full potential of your machinery with our comprehensive vibration analysis solutions tailored for UK food factories. Fill in the form below to request a callback ↓