Seasonal Maintenance Tips: Preparing Lubricants for Peak Production Times

For food processing facilities, peak production periods - such as holiday seasons, summer harvests, and high-demand market trends - place increased stress on machinery and maintenance teams. Ensuring that lubrication systems are prepared for these high-output periods is crucial for maintaining efficiency, preventing breakdowns, and ensuring compliance with food safety regulations.

Food-Grade Lubricants in Beverage Manufacturing: Unique Needs and Solutions

Beverage manufacturing presents unique challenges that demand specialised lubrication solutions. From carbonated drinks to dairy and plant-based beverages, processing equipment must maintain efficiency, hygiene, and safety. Food-grade lubricants are crucial in preventing contamination, ensuring smooth operation, and complying with stringent industry regulations.

The Importance of Lubricant Compatibility in Multi-Line Food Production Facilities

Food production facilities operate multiple production lines, often with different types of machinery and processing conditions. Ensuring lubricant compatibility across all these systems is crucial for maintaining efficiency, preventing contamination, and complying with food safety regulations.

Ensuring Food Safety: The Impact of Lubricants on HACCP Compliance

Hazard Analysis and Critical Control Points (HACCP) is a globally recognised food safety management system designed to prevent contamination risks in food production.

The Role of Grease in High-Pressure Food Processing Equipment

High-pressure food processing equipment is essential for ensuring efficiency, safety, and quality in modern food production. From hydraulic presses and homogenisers to extruders and industrial mixers, these machines operate under extreme conditions, requiring proper lubrication to maintain performance and longevity. Grease plays a crucial role in protecting components, reducing wear, and ensuring smooth operation under high loads.

Exploring the Connection Between Lubrication and Energy Efficiency in Food Factories

Energy efficiency is a top priority for food factories striving to reduce costs, enhance sustainability, and comply with regulatory requirements. While many facilities focus on optimising processes and upgrading equipment, one often-overlooked factor in energy efficiency is lubrication.

The Economics of Preventive Maintenance with Food-Grade Lubricants

Preventive maintenance is a cornerstone of efficient food manufacturing, ensuring operational reliability, compliance, and cost-effectiveness.

Critical Considerations for Selecting a Lubrication Supplier in the Food Sector

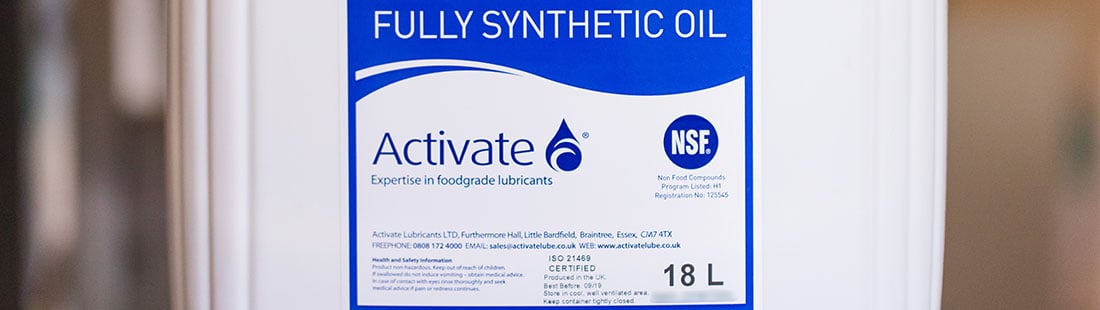

In the food and beverage industry, selecting the right lubrication supplier is not just about ensuring smooth machinery operation—it’s about food safety, regulatory compliance, and operational efficiency. With stringent guidelines like NSF, BRCGS and HACCP in place, choosing a supplier who understands the industry's unique needs is critical. Here are the key factors to consider when selecting a lubrication supplier for your food production facility.

Spotlight on Lubrication Challenges in Dairy Processing Plants

Dairy processing plants operate in highly demanding environments where hygiene, equipment reliability, and food safety are top priorities. Proper lubrication plays a critical role in ensuring smooth operations, preventing contamination, and extending the lifespan of essential machinery. However, dairy processing presents unique lubrication challenges that require specialised solutions.

Training Your Team: How to Build Expertise in Food-Grade Lubrication

Effective lubrication is a critical component of food manufacturing operations, ensuring compliance, efficiency, and long-term cost savings. However, simply using food-grade lubricants is not enough - proper training is essential to maximise their benefits.

Adapting Lubrication Solutions for High-Moisture Environments in Food Factories

Moisture is an inevitable challenge in food factories. From cleaning routines to humid processing environments, high levels of moisture can compromise equipment reliability, safety, and operational efficiency. Selecting and adapting lubrication solutions for such demanding conditions is crucial to maintaining productivity and compliance in food production.

The Role of Sustainable Lubricants in the Food Industry

The food industry is at the forefront of adopting sustainable practices, and one area gaining attention is the use of sustainable lubricants. These eco-friendly alternatives offer a combination of performance, safety, and environmental benefits, making them a valuable solution for modern food production facilities. This blog explores the role of sustainable lubricants in the food industry, their benefits, and how they align with global sustainability goals.

Efficient Storage and Handling of Lubricants: Best Practices

Proper Storage of Food-Grade Lubricants

Maintaining proper storage conditions is crucial for preserving the quality, safety, and efficacy of food-grade lubricants. These lubricants are sensitive to environmental factors, and improper storage can lead to contamination, degradation, or render them unsuitable for use in food processing environments.

Ensuring Audit Compliance with Quality Lubrication Practices

The Importance of Food-Grade Lubricants

In the food manufacturing industry, maintaining a safe and contaminant-free production environment is paramount. Food-grade lubricants play a crucial role in achieving this goal by minimising the risk of contamination and ensuring compliance with stringent regulatory standards.

Role of Lubricants in Enhancing Machinery Lifespan in Food Production

At Activate, we recognise the critical role that proper lubrication plays in protecting and extending the lifespan of industrial equipment, particularly in the food production industry where safety and compliance are paramount.

Emerging Trends and Future Outlook in the Food-Grade Lubrication Industry

The Importance of Food-Grade Lubrication

Food-grade lubrication is essential for maintaining the safety and hygiene of food processing equipment. These specialised lubricants minimise contamination risks, ensuring that harmful substances do not enter the food supply chain. In an industry where even minimal contamination can lead to product recalls, fines, and reputational damage, the importance of using food-grade lubricants is paramount.

The Role of Best Practice Lubrication in Global Asset Care Strategy

In today's industrial landscape, asset management is increasingly recognised as a crucial component of business success.

Buy Food Grade Lubricants in Barrels or Industrial Bulk Containers (IBCs)

When it comes to purchasing food-grade lubricants, businesses have a variety of options ranging from small containers to large barrels and industrial bulk containers (IBCs). While the latter options - buying in barrels or IBCs - may not be suitable for every operation, companies with high lubricant usage can unlock significant advantages by opting for larger volumes.

The Importance of Spill Care in Food Factories: Best Practices for Safety & Compliance

Spill care in food factories is not just a regulatory requirement - it's a crucial part of maintaining a clean, safe, and efficient workplace. From accidental lubricant leaks to chemical spills, the risks associated with poor spill management can lead to contamination, safety hazards, and costly non-compliance penalties.

Single Point Lubricators: How They Work & Why Production Sites Should Use Them

Single point lubricators (SPLs) are automatic lubrication systems designed to supply a consistent and controlled amount of lubricant to a single lubrication point over a designated period. These compact, self-contained units offer a reliable solution for maintaining machinery across various industries, including manufacturing, automotive, and especially food production.

Is WD40 Food Safe?

One of the questions we get asked most frequently - 'is WD40 food safe?' It is understandable as WD40 is such a ubiquitous product and effective for a diverse range of applications.

The Importance of Customer Mindset in Food Grade Lubrication Choices

In the food processing industry, maintaining the highest standards of food safety and quality is paramount. Consumers place immense trust in food manufacturers to deliver products that are not only delicious but also safe for consumption. One critical aspect that often goes unnoticed, yet plays a crucial role in upholding this trust, is the choice of lubricants used in food processing equipment.

Introduction to Auto Lube Systems

Automatic lubrication systems, commonly known as auto-lube systems, automatically apply lubricant such as oil or grease to machinery components at regular intervals while the equipment is running. These systems are used to provide continuous lubrication to bearings, gears, chains, and other moving parts that would normally require frequent manual greasing by maintenance personnel.

The Role of Lubricants in Ensuring Supply Chain Assurance

Navigating the Supply Chain Maze: The Pivotal Role of Lubricants

For those overseeing complex supply chain operations, lubricants play a pivotal role in navigating the intricate maze of logistics and production. Effective lubrication directly impacts equipment reliability and availability, both critical factors in preventing bottlenecks and ensuring smooth flow of goods from procurement to delivery. In the face of the ever-present challenge of minimising downtime, the right lubrication strategy becomes a crucial element in supply chain optimisation.

Maintenance Reliability: A Closer Look at its Importance and Implementation

Reliable Maintenance: A Cornerstone for Operational Excellence in the Food Industry

In the food industry, where production schedules are tight and contamination prevention is paramount, reliable maintenance is not just a necessity, it's a cornerstone for operational excellence. Implementing a robust maintenance reliability program is crucial for ensuring that machinery and equipment operate at peak efficiency, comply with stringent hygiene standards, and minimise the risk of unplanned downtime that can lead to significant production losses.

Lubrication Training: Ensuring Food Safety and Operational Excellence

Insufficient training has been highlighted as a common non-conformity in the previous BRC Global Standard Issue. The Activate team frequently encounters this issue, often due to lubricants being viewed merely as products rather than essential components of a site’s reliability culture.

Condition Monitoring With The MHC Bearing Checker

Condition monitoring involves continuously or periodically assessing the state of machinery and equipment through various techniques such as vibration analysis, thermography, ultrasound, and oil analysis. This process helps detect early signs of wear, damage, or deterioration, allowing maintenance teams to address issues before they lead to equipment failure or costly downtime.

Harnessing Vibration Analysis: Innovative Condition Monitoring in UK Food Factories

In the intricate web of modern manufacturing operations, ensuring the seamless functioning of machinery and production lines is paramount, especially in sectors like food production where quality and safety are non-negotiable.

NSF Classifications: Food Manufacturer Best Practice Guide

NSF International (formerly National Sanitation Foundation) is the leading recognised independent authority for the testing and accreditation of food grade lubricants. This guide has been produced to assist in clarifying the most common NSF categories required for best practice from an audit perspective.

The Importance of GAP Analysis for Regulatory Compliance in the UK Food Industry

Maintaining regulatory compliance is critical for businesses in any industry, but especially for those in the UK food sector, where strict standards ensure the safety and quality of products. A GAP analysis is a powerful tool that helps organisations identify and address areas where their operations may fall short of compliance requirements.

The Importance of Lubrication Training for an Efficient Workforce

Equip Your Team with the Best: The Pivotal Role of Lubrication Training in Maximising Uptime

For engineers and asset managers, understanding the intricacies of lubrication is crucial for maintaining production line uptime. Comprehensive lubrication training equips maintenance teams with advanced knowledge of lubricant properties, application techniques, and monitoring strategies. This knowledge is pivotal in preventing unscheduled downtime and ensuring continuous, efficient production.

Leveraging Food-Grade Lubricants for Sustainable Growth in Integrated Fresh Produce Companies

In today's eco-conscious business landscape, fully integrated fresh produce companies, operating from "grower to marketing", are increasingly realising the significance of sustainable practices. These forward-thinking organisations acknowledge that their dedication to environmental responsibility not only aligns with global sustainability objectives but also enhances their corporate image, regulatory compliance, and overall performance.

Why Oil Analysis is Essential for Ensuring Machinery Health

Advanced Tribological Insights: The Impact of Oil Analysis on Machinery Health

In the realm of industrial machinery maintenance, the significance of oil analysis cannot be overstated. It's a critical tool of the Reliability-Centred Maintenance (RCM) approach. Through advanced oil analysis, Activate Lubricants provides crucial tribological insights, identifying wear patterns, lubricant contamination, and degradation before they escalate into major mechanical failures.

The Hidden Impacts of Approximate Lubrication on Food Factory Reliability, Compliance, & Profitability

In the intricate world of food manufacturing, where precision and efficiency are paramount, the importance of proper lubrication cannot be overstated.

Food-Grade Lubricants in Animal Feed Pellet Manufacturing

In the animal feed pellet manufacturing sector, the use of food-grade lubricants is not just a matter of choice; it is a regulatory mandate in the UK. As the industry focuses on maintaining food integrity and safety, the adoption of food-grade lubricants is gaining prominence.

Spotlight on Activate’s Offerings: Lubricants and Storage Systems

Discover the excellence of Activate’s Lubricants and Storage Systems. Visit our blogs for more insights and contact us to explore how our tailored solutions can revolutionise your lubrication strategy. Partner with us for a future of operational excellence and sustainability.

Try market-leading foodgrade lubricants in a no-obligation 4-wk trial

In the dynamic landscape of manufacturing, efficiency isn't just a goal—it's the cornerstone of success. For industries like food production, where compliance, reliability, and profitability are paramount, finding the right lubrication solutions is a game-changer.

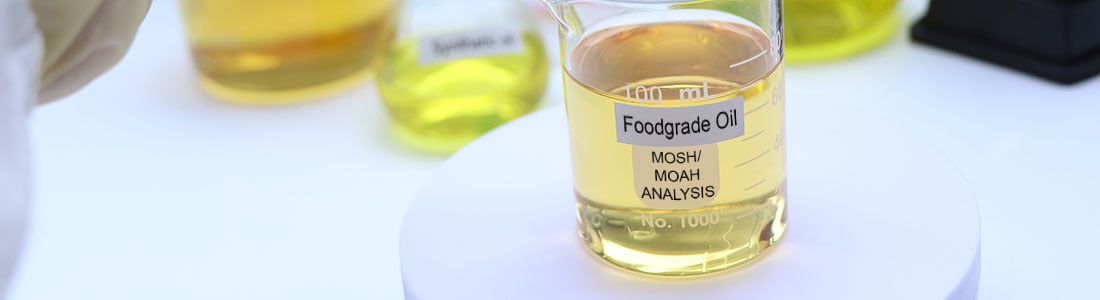

EFSA Highlights Need for Stricter Mineral Oil Regulation in Food

The European Food Safety Authority (EFSA) recently issued an updated risk assessment on mineral oil hydrocarbons (MOHs) in food, shedding light on critical concerns and gaps in understanding the impact of these compounds on human health.

Enhancing Animal Pellet Feed Sector Reliability

In March 2020, a new regulation mandated the use of food-grade lubricants in the UK animal pellet feed sector. This article provides an overview of the adoption of food-grade lubricants in this sector and presents a case study highlighting the benefits of choosing a high quality, application specific product.

The Crucial Role of Lubrication Training in the Food Industry

In the dynamic and demanding landscape of the food industry, engineers play a pivotal role in ensuring the smooth operation of machinery and equipment. Among the various maintenance practices, the significance of lubrication cannot be overstated.

Global QSRs Lead Move to Mineral Oil-Free Food Packaging

With reports of big brand Quick Service Restaurants (QSRs) directing packaging suppliers to transition to mineral oil-free lubricants from January 2024, ahead of proposed EU legislation banning Mineral Oil Saturated Hydrocarbons (MOSH) and Mineral Oil Aromatic Hydrocarbons (MOAH) in food packaging, the race is on to achieve compliance.

Best Practice Lubrication Benefits: A 5-step plan you can implement.

In the demanding landscape of modern food manufacturing, there's one component that often remains unsung despite its monumental importance: lubrication.

A 5-step guide in Understanding Customer Challenges in Lubrication.

In any industry, understanding customer challenges is pivotal to providing effective solutions and forging lasting relationships.

Core Values: The Foundation of Activate Lubricants

In any industry, the pulse and identity of a company can be discerned not just from its products or services, but from its core values. These values drive decisions, shape cultures, and influence relationships. At Activate Lubricants, our dedication to excellence within the field of food-grade lubrication is underpinned by a set of foundational values that govern every facet of our business.

The Science Behind Food-Grade Lubrication

The world of food production relies on machinery to meet demand. But how do we ensure these machines run smoothly without contaminating the very food they produce? The answer lies in food-grade lubrication, a marvel of science tailored specifically for the food industry. Dive in with us as we explore the intricate science behind these lubricants.

Food factory chemical control

Inadequacies in chemical control in food production sites have been identified as a common non-conformance with the BRC Global Standard. In our experience, the level of awareness of the requirements for effective control of chemical contaminants in food production areas differs wildly between different production sites.

Cross-referencing foodgrade lubrication partners

A short guide to maximising foodgrade lubrication performance and value for money

Culture shock: positive change for positive outcome

A food production business is a collective entity whose lifeforce and output is influenced by collective and individual behaviours, the attitudes of employees and management, and the working environment. In a similar way, production line maintenance and reliability are influenced by collective factors present in (or, indeed, absent from) the overall maintenance culture.

Buy UK-made foodgrade lubricants

With the current challenges posed by the global pandemic fallout, the post-Brexit landscape, the cost of living crisis (we could go on…), leveraging products of UK manufacture and UK-based services offers huge advantages for food production, food packaging and pharmaceutical businesses.

Compatibility of different foodgrade lubricants

When a food production site switches to Activate Lubricants, engineers are often concerned about the compatibility of our products with existing stocks from their previous supplier. Despite moving to a much simpler and easier to use system, change always requires a period of familiarisation before becoming second nature.